PLANETARY MIXERS WITHOUT VACUUM

Mixing and defoaming without vacuum in one step – with patented defoaming mode

Successor to the ARE-250 planetary centrifugal mixer - now with higher speed and PC interface. Highly efficient mixing without agitator. The device has a mixing and a defoaming mode. With the defoaming mode, many materials can be degassed without a vacuum.

Mixing and defoaming without vacuum in one step

Our entry-level planetary centrifugal mixer. Highly efficient mixing without stirrer.

Mixing and defoaming for technical centers – without vacuum in one single step.

The ARE-500 – A planetary mixer for technical centers and small-scale production where process times matter. Highly efficient mixing without stirrer. Often defoaming is possible without vacuum with the integrated Defoaming Mode with adjusted revolution/rotation ratio.

SOLDER PASTE MIXERS

Mixing, warming and defoaming of solder paste – without vacuum in one single step.

A planetary mixer, designed especially for solder pastes and similar media like screen printing. The samples are homogenized, deaerated and warmed up by overlaying the two rotation movements. Unlike the allrounder ARE-250, the maximum load is about doubled, to enable the use of 500 g net standard solder paste containers. The maximum speed is likewise reduced to 1.200 RPM, which is completely enough for solder pastes. This makes the SR-500 the Thinky mixer with the best value in our portfolio.

PLANETARY MIXERS WITH VACUUM

Mixing and defoaming in one step, enhanced by internal vacuum pump

Highly efficient vacuum laboratory mixer: uses contactless mixing method for homogenizing, disperging and defoaming with integrated vacuum pump, directly in the container without stirrer! The integrated vacuum pump is able to remove even the smallest of air bubbles.

Mixing and defoaming in one step with vacuum – technical center scale

The ARV-501 is a vacuum mixer for technical centers up to 700 g gross mixing capacity. The operator’s touch panel is similar to the ARV-310P. The RS232C interface is also included. Schnittstelle für eine PC-Verbindung ist vorhanden. Maximum speed in mixing mode is 1.500 UPM, in defoaming mode 2.000 UPM. Included is the pump undercarriage PU-501 with integrated vacuum pump.

Mixing and defoaming of two samples in one step with vacuum – technical center scale

The ARV-931Twin – a highly efficient dual vacuum mixer: enables contactless mixing, dispersing and defoaming in a container without stirrer! The integrated vacuum pump removes even the smallest of air bubbles. The twin cup holder system effectively doubles the capacity of the mixer.

Mixing and defoaming in a single step for production, enhanced by integrated vacuum

The ARV-5000 – a highly efficient vacuum mixer for production: Enables contactless mixing, disperging and deaeration without foaming, directly in the container! The integrated vacuum pump removes even the smallest of bubbles.

Mixing and defoaming of two containers simultaneously for production, enhanced by integrated vacuum.

Der ARV-10k Twin is the largest commercially available planetary vacuum mixer in the world. With a capacity of 2x 10 litres (net) or 2x 10 kg (net) it is fit for many production applications. The integrated SPC control and the CVT transmission enable maximum flexibility for the setup. Enables contactless mixing, disperging and deaeration without foaming, directly in the container! The integrated vacuum pump removes even the smallest of bubbles.

AUXILIARY DEVICES FOR PLANETARY MIXERS

Sensor for online data acquisition of temperature and rotation speed for small and intermediate scale mixers

The Thinky Multi-Sensor is able to measure speed and temperature and record them using software. The connection to the PC is via Bluetooth® and the energy supply is via a coin cell battery that is designed for approx. 100 hours of operation.

Under-carriage cooling module for ARE-250, ARM-310 and SR-500.

The ENs-10 cooling system is an accessory for Thinky’s small planetary mixer series. It pushes warm air out of the mixer chassis and lowers the temperatures on the inside by 10 °C on average.

Syringe filler for continous operation. bubblefree filling of syringes with Luer-Lock-thread.

Syringe fillers help transfering already bubble-free material into syringes without inducing air into the system. The ARC-40H can be used for 1-4 syringes of 3-10 ml, for 1-2 syringes of 20-55 ml the ARC-55H. The mixing cup is taken out of the Thinky mixer and directly placed in the syringe filler. It presses the material bottom to top under vacuum trough the tip into the syringe. Continous operation with syringe exchange is possible.

ACCESSORIES FOR PLANETARY MIXERS

All Thinky mixers are shipped by default with a few reusable containers made of HDPE. They are well-made, offer the highest capacity and the best sealing capabilities.

Available are different types of disposable cups, reusable cups, as well as special shapes of containers – each with matching adapters. Furthermore, we offer different syringe adapters to deaerate filled syringes after material transfer. The choice of the right container is very important for the success of a mixing process. The actual force applied to the material is based on the diameter of the cup. The filling height is also of paramount importance.

Thinky mixers can be used with various disposable cups. They offer advantages when cleaning of reusable cups is too difficult or not possible.

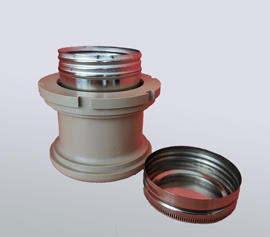

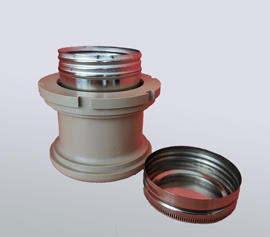

Thinky offers various types of disposable cups, mostly made of Polypropylene, for instance our open disposable cups that look like drinking cups. For smallest amounts we recommend our screw cap jars from 12 to 125 ml which can be used starting with 1 ml. The largest amount can be achieved with the 250 ml PP screw cap jar.

Thinky offers a wide range of syringe adapters for EFD- and Musashi-type syringes, as well as EFD/Semco cartridges. There are adapters for single or multiple syringes, or even several different sizes.

The choice of the right container is very important for the success of a mixing process. The actual force applied to the material is based on the diameter of the cup. The filling height is also of paramount importance. Syringe and cartridge adapters are mainly intended to deaerate an already homogenous material. Mixing is difficult due to the improper aspect ratio between diameter and height, so it depends on viscosities and actual filling height.

Special adapters and containers from Thinky are being produced in small numbers or individually at customer request. This also includes special materials and container shapes.

Thinky offers a range of special adapters for their mixers and also produces custom adapters for your own containers. We also offer special container shapes to increase turbulence and shear rate inside the cup, for instance to break agglomerates or achieve homogenization at higher differences in material density. The choice of the right container is very important for the success of a mixing process. The actual force applied to the material is based on the diameter of the cup. The...