LAB PRESSURE REACTORS – 0.25-5.0 LITRES

Safety and flexibility for a wide range of pressure applications in steel and glass vessels

Flexible, modular pressure reactor system for laboratory/technical laboratory applications for volumes from 0.25 to 5 litres and pressures between 6 and 200 bar. The robust stainless-steel frame with polycarbonate door allows safe pressure reactions with glass vessels. An optional vessel lift with safety fast action closure provides easy and safe handling.

Flexible and robust- even under high pressure

The versoclave is an extremely flexible pressure reactor system for steel reactors between 0.5 and 5 liters in stainless steel, Hastelloy and special alloys. The system is equipped with 60 bar reactors with/without sight glass and can be upgraded up to 200 or 350 bar as a standard option. The open frame offers enough space for process-technical attachments.

Compact, modular, excellent price/performance ratio, ss/metal pressure reactor system with 0.5 / 1 liter volumina

Modular pressure reactor system for steel and glass reactors of 0.5 - 1 litre. For safe performance of pressure reactions in glass reactors, the Uniclave has a shatterproof housing with polycarbonate sliding door.

SMALL PRESSURE REACTOR – 10-300ML

Modularity and safety for a wide range of pressure applications in steel and glass vessels

Flexible reactor system for different applications, optionally with steel or glass reactors from 100-300ml. Visual process control and monitoring of your reaction can be carried out in the glass reactors up to 10 bar. Use steel reactors, you can work up to 100 bar and optionally use PTFE Inliner.

small volumina – strong magnetic drive

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 100-300ml. The compact system can be placed in every fume cupboard. A safety fast action closure allows quick and easy opening and removal of the reactor without tools.

Safety and flexibility with small scale glass and steel reactors

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 50-300ml. The robust stainless-steel frame with polycarbonate door also allows safe pressure reactions with glass pressure vessels. The safety fast action closure allows a quick vessel change or cleaning - without tools.

PRESSURE REACTORS FOR KILO LAB & PRODUCTION

Safe pressure reactions up to 20 litres in laboratory/kilo lab or in small scale production

The Buchi Kiloclave is ideal for up-scaling processes or small scale production, reactors between 0.5 and 20 liters can be used on the same cover plate. Due to its robust frame with hydraulic reactor lift and tilt function, it is particularly suitable for larger reactors and process-technical attachments.

Safe pressure application on a pilot scale up to 500 litres

Büchi builds pilot plants for process engineering pressure and vacuum applications mainly for the chemical and pharmaceutical industry. Depending on the process and process media, the plants are designed in different materials and manufactured for pressures up to 200 bar and volumes up to 300 liters. Typical applications are the pilot plant for process optimization or process development as well as production plants for the manufacture of small quantities.

HIGH PRESSURE REACTORS

Safe and comfortable working under high pressure

The midiclave is a flexible high-pressure reactor for a pressure range of up to 200 bar. It can be operated with various interchangeable metal pressure vessels up to 1 litre volume with or without sight glasses. Thanks to the built-in safety precautions and the fast action closure, pressure reactions can be carried out safely and comfortably.

Reach new dimensions in terms of pressure and temperature

The Buchi novoclave is designed for extreme conditions of up to 500 bar and up to 500°C. For supercritical reactions, hydrogenation, material and catalyst tests, reactors between 100 and 600 ml can be used. The reactors are tempered by electrical heating with PID controller and built-in automated tap water cooling, magnetic valve controlled.

GASDOSING-/HYDROGENATION SYSTEMS, PARALLEL REACTOR

BPC 2 - gas dosing unit for reliable and reproducible hydrogenation

The Buchi BPC 2, which consists of a gas regulator and control unit, is a fully integrated gas dosing system for the safe and reproducible performance of hydrogenations, oxidation reactions (polymerization) and for catalyst research. The unique volumetric dosing system is characterized by high reproducibility and dosing accuracy.

Safe, Flexible and Efficient

The PPR parallel reactor system enables safe, automated and parallel reactions under pressure in 2 to 6 laboratory reactors. Reactors up to 300 ml and 150 bar are available. Hydrogenation and catalyst tests can therefore be carried out quickly and efficiently.

MEASURE, CONTROL & AUTOMATION

Data collection and automation - uncomplicated and reliable.

The Buchi measuring and control units offer you direct communication with the pressure reactors. The devices are flexibly configurable and designed for measuring and displaying various process parameters in chemical laboratories and process plants - also in the EX sector. Büchi also offers you the automation of individual processes up to full automation with recipe control.

Play it safe and use EX-protected and appropriately certified reactor technology.

Even in small volumes, in the laboratory or kilolab, explosion protection can play an important role. Because the smallest amounts of liquid educts or products can form a dangerous amount of an explosive mixture as a gas volume.

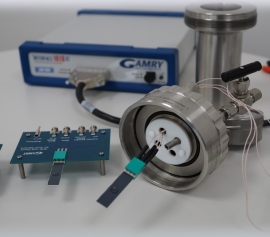

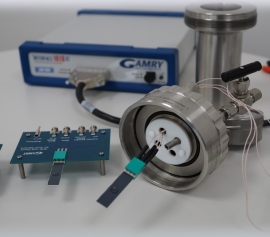

ELECTROCHEMISTRY IN AN AUTOCLAVE

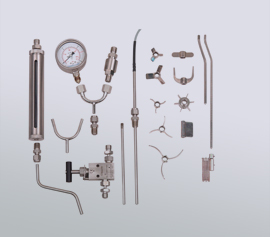

Electrochemical synthesis, the characterization of catalysts, corrosion measurements or basic research on new electroactive species can also be carried out at higher pressures and beyond room temperature with Gamry Instruments potentiostat in an autoclave from Büchi.

For any application in an autoclave, safety always comes first due to the enormous amount of stored energy at high pressure and temperature. Our autoclaves from Büchi Glas Uster are equipped with appropriate measuring and safety devices ex works. Thanks to the comprehensive selection of vessels, your experiment can always take place in the smallest possible volume. By means of pressure-tight cable feed-throughs, the contact between the samples and the potentiostat can be established without compromising on the temperature and...