BORATE FUSION FLUXER

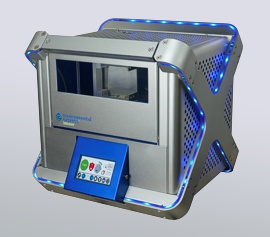

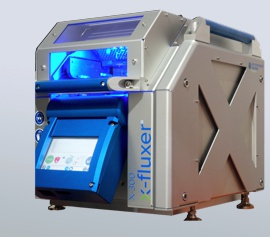

Device with one sample position in a compact format without compromising on robustness, purely electrical without gas or other media, for the production of melting tablets or acid solutions

The new Katanax X-Fluxer X-100 (available soon) with one sample position has the same unique components and features as its larger brothers X-Fluxer X-300 and X-600, ensuring fast, simple and above all reproducible sample preparation with maximum efficiency. Both glass disks (beads) and acid solutions can be produced.

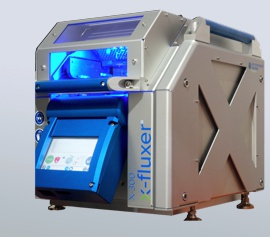

The Katanax Fluxer X-300 - preparation of glass disks (beads) for XRF or solutions for ICP with one, two or three sample positions, fully electric without gas or other media ... Fusion has never been so easier and safer.

The modular X-300 from Katanax has an intuitive touchscreen operation and works fully automatically. Seven independently controlled heating elements made of acid-resistant ceramic guarantee exact temperature control and thus reproducible results with a long service life. The optionally available stirring module can remain installed permanently and enables a quick change from preparing glass disks to solution preparation.

The Katanax X-Fluxer® X-600 – preparation of up to 6 glass disks for XRF or up to 6 solutions for ICP in parallel - fully electrically without gas or other media ... Fusion has never been so easier and safer.

The X-600 from Katanax has an intuitive touchscreen operation and works fully automatically. Seven independently controlled heating elements made of acid-resistant ceramic guarantee exact temperature control and thus reproducible results with a long service life. The optionally available stirring module can remain installed and enables a quick change from preparing glass disks to solution preparation.

The automatic dosing machine Katanax XFP-01 FluxPenser® - precise and reproducible weighing of flux - including balance and LIMS compatibility.

There are two operating modes to choose from for dispensing fusion flux, either dispensing a defined amount (for ICP) or dispensing a certain flux / sample ratio (for XRF). The correct amount of flux is calculated automatically, the accuracy of dispensing is within 1 mg.

HIGH ENERGY BALL-MILL´S

Compact laboratory ball mill for small sample quantities - grinding and homogenizing in 2ml, 3.5ml, 5ml, 7ml and 12ml tubes - up to six grinding vials at the same time.

The Cole-Parmer BM-200 Mixer / Mill® laboratory ball-mill allows the use of grinding vials made of plastic, stainless steel, agate or tungsten carbide. The various sample matrices are disrupted with highest efficiency using a unique horizontal figure eight grinding movement at a maximum speed of 3500 rpm.

The BM-400 Mixer / Mill® high-energy ball mill from Cole-Parmer (formerly SPEX SamplePrep 8000M Mixer/Mill®) - grinding, mixing and mechanical alloying with one grinding vial holder

The unique grinding movement of the BM-400 Mixer / Mill, resembling the shape of a lying figure eight, represents the standard in the application area of "mechanical alloying". The operating time for this application can be extended to 10,500 minutes. Other areas of application are the grinding of rock, ceramics and slag. Grinding vials made of steel, agate, tungsten carbide, zirconium and plastic in different volumes up to 50mL can be used.

The BM-450 Mixer / Mill® high-energy ball mill from Cole-Parmer (formerly SPEX 8000D Mixer/Mill®) - grinding, mixing and mechanical alloying with double capacity.

The unique grinding movement of the BM-450 Mixer / Mill®, resembling the shape of a lying figure eight, represents the standard in the application area of "mechanical alloying". The operating time for this application can be extended to 10,500 minutes. Other areas of application are the grinding of rock, ceramics and slag. Grinding vials made of steel, agate, tungsten carbide, zirconium and plastic in different volumes up to 2 x 50mL can be used.

RING & PUCK MILLS

For the extremely fast size reduction of hard, medium-hard, brittle and fibrous samples to analytical fineness with the Cole-Parmer SM-200 Shatterbox® (formerly SPEX 8530 Shatterbox®). Dry or in suspension.

The Cole-Parmer SM-200 Shatterbox® enables the grinding of 2-150g sample material per run with a maximum running time of 10 minutes. Depending on the hardness of the sample, grinding dishes made of hardened steel, tungsten carbide, aluminum oxide or zirconium oxide are available. To protect the user, the device has a safety interlock, the sound insulation ensures the best possible protection against excessive noise.

For the extremely fast size reduction of hard, medium-hard, brittle and fibrous samples to analytical fineness. Dry or in suspension.

The Cole-Parmer SM-300 Shatterbox® enables the grinding of 5-150g sample material, therefor ten individually configurable grinding programs are available. Depending on the hardness of the sample, grinding dishes made of hardened steel, tungsten carbide, aluminum oxide or zirconium oxide are available. To protect the user, the device has a safety interlock, the sound insulation ensures the best possible protection against excessive noise.

PELLET PRESSES

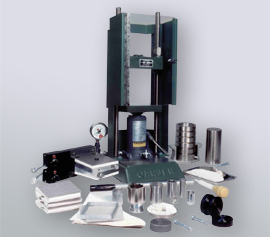

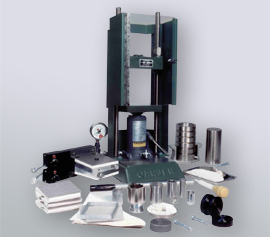

Pressing pellets for IR-analysis - fast and economical ... the SPEX 3626 manually controlled laboratory press - an easy-to-use press with a pressure range of up to 10.9 tons for using the 13mm die set.

After closing the safety shield, the desired pressure for pressing the pellet is applied manually using the hand lever; the pressure can be read on the pressure gauge. Holding and relief time are regulated manually by the user.

Pressing pellets for IR- and XRF-analysis - fast and economical ... the SPEX 3621 manually controlled laboratory press - an easy-to-use press with a pressure range of up to 10.9 tons for using various die set´s.

After closing the safety shield, the desired pressure for pressing the pellet is applied manually using the hand lever; the pressure can be read on the pressure gauge. Holding and relief time are regulated manually by the user.

Pressing pellets for IR- and XRF-analysis - fast and economical ... the SPEX 3622 manually controlled laboratory press – the “allrounder” with a pressure range of up to 22.7 tons for using various die set´s.

After closing the safety shield, the desired pressure for pressing the pellet is applied manually using the hand lever; the pressure can be read on the pressure gauge. Holding and relief time are regulated manually by the user.