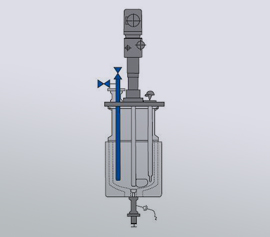

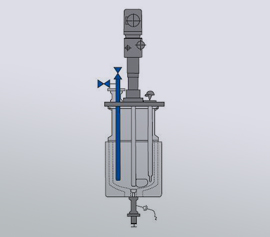

SMALL PRESSURE REACTOR – 10-300ML

Modularity and safety for a wide range of pressure applications in steel and glass vessels

Flexible reactor system for different applications, optionally with steel or glass reactors from 100-300ml. Visual process control and monitoring of your reaction can be carried out in the glass reactors up to 10 bar. Use steel reactors, you can work up to 100 bar and optionally use PTFE Inliner.

small volumina – strong magnetic drive

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 100-300ml. The compact system can be placed in every fume cupboard. A safety fast action closure allows quick and easy opening and removal of the reactor without tools.

Safety and flexibility with small scale glass and steel reactors

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 50-300ml. The robust stainless-steel frame with polycarbonate door also allows safe pressure reactions with glass pressure vessels. The safety fast action closure allows a quick vessel change or cleaning - without tools.

PRESSURE REACTORS FOR KILO LAB & PRODUCTION

Safe pressure reactions up to 20 litres in laboratory/kilo lab or in small scale production

The Buchi Kiloclave is ideal for up-scaling processes or small scale production, reactors between 0.5 and 20 liters can be used on the same cover plate. Due to its robust frame with hydraulic reactor lift and tilt function, it is particularly suitable for larger reactors and process-technical attachments.

Safe pressure application on a pilot scale up to 500 litres

Büchi builds pilot plants for process engineering pressure and vacuum applications mainly for the chemical and pharmaceutical industry. Depending on the process and process media, the plants are designed in different materials and manufactured for pressures up to 200 bar and volumes up to 300 liters. Typical applications are the pilot plant for process optimization or process development as well as production plants for the manufacture of small quantities.

HIGH PRESSURE REACTORS

Safe and comfortable working under high pressure

The midiclave is a flexible high-pressure reactor for a pressure range of up to 200 bar. It can be operated with various interchangeable metal pressure vessels up to 1 litre volume with or without sight glasses. Thanks to the built-in safety precautions and the fast action closure, pressure reactions can be carried out safely and comfortably.

Reach new dimensions in terms of pressure and temperature

The Buchi novoclave is designed for extreme conditions of up to 500 bar and up to 500°C. For supercritical reactions, hydrogenation, material and catalyst tests, reactors between 100 and 600 ml can be used. The reactors are tempered by electrical heating with PID controller and built-in automated tap water cooling, magnetic valve controlled.

GASDOSING-/HYDROGENATION SYSTEMS, PARALLEL REACTOR

BPC 2 - gas dosing unit for reliable and reproducible hydrogenation

The Buchi BPC 2, which consists of a gas regulator and control unit, is a fully integrated gas dosing system for the safe and reproducible performance of hydrogenations, oxidation reactions (polymerization) and for catalyst research. The unique volumetric dosing system is characterized by high reproducibility and dosing accuracy.

Safe, Flexible and Efficient

The PPR parallel reactor system enables safe, automated and parallel reactions under pressure in 2 to 6 laboratory reactors. Reactors up to 300 ml and 150 bar are available. Hydrogenation and catalyst tests can therefore be carried out quickly and efficiently.

MAGNETIC COUPLINGS & MAGNETIC STIRRER DRIVES

under pressure or vacuum - strong and absolutely tight

Buchi offers a perfected and successful drive concept for different volumes and torque ranges. The pure magnetic coupling without rotating outer parts reliably and safely ensures the power transmission from the motor to the agitator and offers the highest level of safety for the operator. ATEX versions are available.

compact, powerful drives combined with modern control technology

Buchi's magnetic drives combine an electric motor as a drive and the proven Büchi magnetic couplings for power transmission in a single compact unit. The Büchi Cyclone is available in the version up to 75 Ncm and up to 300 Ncm.

MEASURE, CONTROL & AUTOMATION

Data collection and automation - uncomplicated and reliable.

The Buchi measuring and control units offer you direct communication with the pressure reactors. The devices are flexibly configurable and designed for measuring and displaying various process parameters in chemical laboratories and process plants - also in the EX sector. Büchi also offers you the automation of individual processes up to full automation with recipe control.

Play it safe and use EX-protected and appropriately certified reactor technology.

Even in small volumes, in the laboratory or kilolab, explosion protection can play an important role. Because the smallest amounts of liquid educts or products can form a dangerous amount of an explosive mixture as a gas volume.

PRESSURE REACTORS

A flame polished glass connection!

Safe, tight and reliable connections are the crucial point for dependable operations of glass reactors in the chemical and pharmaceutical industry. The Buchi company founders recognized at an early stage that the flexibility of each individual glass joint is of huge importance. The unique buchiflex connection was invented as the basis of a complete modular glass system with interchangeable components.

Combined stirred filter reactor - one device for different reactions and process steps

The filter reactor (10-50 litres / optionally up to 250 litres) is a glass reactor with filtration capability that can be used for stirring, crystallising, homogenising, dissolving solids and separating solids. The glass apparatus with robust PFA-coated cover plate is located in a solid stainless steel frame.

![Buchi MiniPilot [2 …15 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-2-15-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)

Stirred glass vessel [2 … 15 liter] with PFA-coated robust steel cover plate

The Reactor's explosion proof design (ATEX) and inert materials allow safe processing of solvents and acids in a completely sealed reaction vessel. The compact standard reactor setup can easily be modified, interchangeable reaction vessels of 2, 5, 10 and 15 liters including interchangeable stirrers are available.

![Buchi MidiPilot [15 … 30 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruerhrapparat-15-30-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)

Stirred glass vessel [15 … 30 liter] with PFA-coated robust steel cover plate

The midiPilot is our sturdy multipurpose glass reactor for small volumes. It is specifically designed for applications in kilo lab, for chemical process development and GMP complaint API syntheses. The system is also available as clean-room setup.

![Buchi BR Glass reactor [15 … 60 (100) liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-15-60-100-Liter-mit-Destillationsaufbau-und-Ex-gesch-Motor_S.jpg)

Glass reactor BR with destillation system

The BR type chemReactor is a basic pilot reactor system for chemical process development, scale-up, process simulation and kilo-scale cGMP production in batch and semi-batch operation.

![Buchi GR System [15 … 60 (100) Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruerhrapparat-15-60-100-Liter-mit-Destillationsaufbau-und-ATEX-gesch-Motor_S.jpg)

Stirred glass vessel with multipurpose glass setup for destillation.

The GR type chemReactor is a complete pilot reactor system for chemical process development, scale-up, process simulation and kilo-scale cGMP production in batch and semi-batch operation. A lot of options are possible.

![Buchi CR-System [15 … 250 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-15-250-Liter-mit-Destillationsaufbau-und-Ex-gesch.Motor_S.jpg)

Stirred enamel vessel with multipurpose glass setup for destillation.

Reactor [CR-Type] with solid jacketed glass lined steel bottom stands for solid construction, excellent heat transfer, stable process conditions and temperatures, and a glass section to easily improve and control chemical reactions by visual observation.

Glass setup, Glass parts for stirred vessels

Chemical process equipment consisting of glass lined reactors or mixing tanks with distillation overhead in borosilicate glass can be operated at full vacuum and low pressure. A large variety of chemicals can be processed in such plants due to the highly corrosion resistant materials used.

Nutsch filters with many options

Buchi nutsch filters can easily be combined with our reactors for solid / liquid separation after the synthesis. The inert materials allow safe processing in a inert atmosphere of a wide range of solvents and acids, completely under full vacuum.

Stirred vessel – made of glass, glass lined steel, steel.

Mixing vessels are frequently used for stirring, dissolving, mixing, extraction and other processes in kilo-labs and pilot plants. Jacketed Glass reactors permit heat exchange for better dissolving and crystallization. Mobile mixing vessels can be transported with their content for further processing.

Glass scrubber

Gas scrubbers are used to neutralize corrosive exhaust gas from reactors. Depending on the scrubbing liquid, they can be used for caustic or acidic vapors. Gas scrubbers are equipped with an ETFE lined, corrosion resistant magnetic coupled pump.

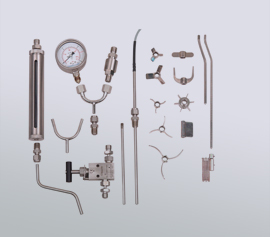

REACTORS-ACCESSORIES

Many accessories for different applications in a stirred vessel.

Different accessories helps to complete and realise your process, for example: pH measurement, pH control, gas inlet tube, sampling system, solid charger, pumps, thermostate, isolation, flow control sensors and regulators, CIP equipment, spray nozzle, load or weighing cell, glove box, ….

POTENTIOSTAT - MULTI-CHANNEL SYSTEMS

The IMX8 (Electrochemical Multiplexer) offers higher experimental throughput by performing automatic sequential measurements. With some limitations compared to multi-channel systems is a cost effective alternative for many applications.

With the IMX8, the throughput of electrochemical experiments in the laboratory can be increased from one channel to a total of eight channels within a reasonable budget. The ECM8 is the ideal additional system for the application field of corrosion inhibitor development, corrosion testing methods and their field tests, assessment of the impedance of coatings and development of chemical sensors.

The Gamry EIS Box 1010 consists of an Interface 1010 base unit and an electrochemical multiplexer optimized for impedance spectroscopy (EIS) on batteries, fuel cells and super capacitors up to ±12 V.

With the EIS Box 1010, the detailed characterization of multiple batteries using the sophisticated method of electrochemical impedance spectroscopy (EIS) is intuitively possible and at the same time offers reliable results at high throughput. This efficiently accelerates tasks in quality assurance, material development and basic research of electrochemical energy storage devices.

The Gamry EIS Box 5000 consists of an Interface 5000 base unit and an electrochemical multiplexer optimized for impedance spectroscopy (EIS) on batteries, fuel cells and super capacitors up to ±6 V.

With the EIS Box 5000, the detailed characterization of multiple batteries using the sophisticated method of electrochemical impedance spectroscopy (EIS) is intuitively possible and at the same time offers reliable results at high throughput. This efficiently accelerates tasks in quality assurance, material development and basic research of electrochemical energy storage devices.

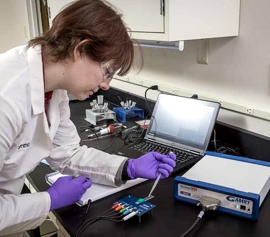

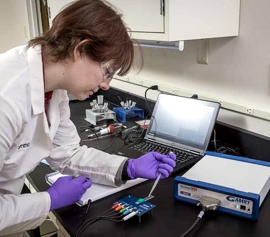

LABORATORY COURSE / TRAINING / TEACHING

The entry-level electrochemistry package consists of 5 laboratory experiments with digitally available operating instructions and accessories as well as the Gamry System Interface 1010T Potentiostat/Galvanostat/ZRA - with this combination, the entry into electrochemistry is guaranteed to succeed at an attractive price.

Gamry´s Interface 1010T Potentiostat/Galvanostat/ZRA and Starter Pack reduce 11 available experiments in electrochemistry from the Laboratory Course to a cost-efficient 5 experiments in order to make methods and theories of electrochemistry available to an even wider audience in an efficient and comprehensive way. Within the package you will receive the support you need to familiarize yourself, students or employees with the various methods of electrochemistry.

The Laboratory Course in Electrochemistry is a modular laboratory kit meant as a comfortable and understandable introduction to electrochemistry for students or research assistants.

Gamry´s Laboratory Course in Electrochemistry teaches the methods and theories of electrochemistry efficiently and comprehensively. With the combination of a Gamry system at an entry-level price, a basic kit and the choice out of a total of 11 individual laboratory experiments, you will receive the support you need to familiarize yourself, students or employees with the various methods of electrochemistry.

SOFTWARE

Gamry has developed its own software for each important application in electrochemistry and offers a very simple and intuitive handling through open source scripting, flexible and uncomplicated, even the customized experiment as well as with other programming languages such as LabView, C++, etc.

In a Gamry system, the electrochemical experiment consists of two separate operations, each in its own software environment. The recording of the measured data is done with modifiable scripts programmed in "Explain" in the Gamry Framework and their evaluation with modifiable Microsoft Visual Basic for Applications (VBA) scripts in the Echem Analyst.

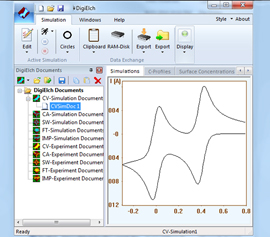

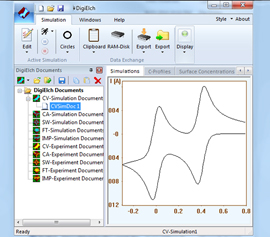

DigiElch is a simulation program with a unique selection of different functions for a variety of electrochemical experiments

With DigiElech, electrochemical reactions on typical electrode geometries, thin film electrode arrays and on two-dimensional microelectrodes can be simulated very accurately. The voltage drop due to the uncompensated electrolyte resistance or iR drop as well as charge and discharge currents through the electrochemical double layer can also be taken into account during simulation.

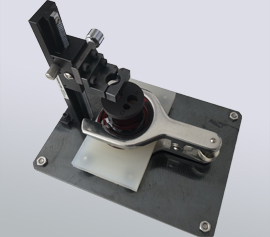

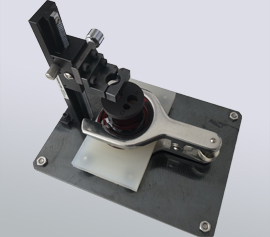

SPECTROELECTROCHEMISTRY

For synchronization of spectroscopic information with the electrochemical change of a redox pair Gamry offers the right system from UV to NIR

The Gamry spectroelectrochemical system is designed to combine electrochemical techniques with standard spectroscopic methods such as absorption, transmission, and fluorescence in the UV-VIS and VIS-NIR range. Both methods are synchronized either together in the Gamry Framework software or by spectrometer triggering in separate software environments for Gamry potentiostat and spectrometer.

Synchronization of electrochemical changes of a redox reaction with complex scattered light spectroelectrochemistry or Raman spectroelectrochemistry

Raman spectroelectrochemistry combines the near-surface identification and interpretation of inelastic scattering by rotational, vibrational and phonon transitions with electrochemical redox reactions. These transitions can be triggered at the working electrode or molecules bound to it after excitation with a monochromatic light source of high power density (laser)

![Buchi MiniPilot [2 …15 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-2-15-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)

![Buchi MidiPilot [15 … 30 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruerhrapparat-15-30-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)

![Buchi BR Glass reactor [15 … 60 (100) liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-15-60-100-Liter-mit-Destillationsaufbau-und-Ex-gesch-Motor_S.jpg)

![Buchi GR System [15 … 60 (100) Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruerhrapparat-15-60-100-Liter-mit-Destillationsaufbau-und-ATEX-gesch-Motor_S.jpg)

![Buchi CR-System [15 … 250 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-15-250-Liter-mit-Destillationsaufbau-und-Ex-gesch.Motor_S.jpg)